Introduction

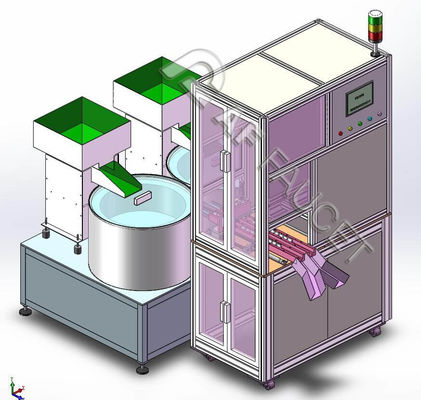

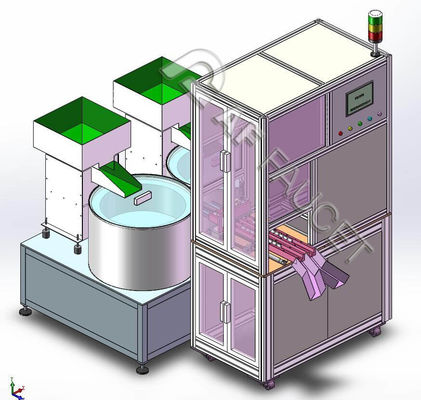

This automatic laser marking machine can print a Logo or symbol on the cartridge’s body shell. Automatically loading, feeding, counting, and printing. This line is stable, and easy operation, all the symbols, logos, and graphics can be edited, and modified in the control system.

1. This laser marking machine is suitable for plastic ceramic cartridge's body shell's logo printing

2. The laser marking logo is clear, durable, and high aesthetic outlook.

3. Cycle time: 1.5 seconds/set, productivity: 15000 sets / 8 hrs.

4. The machine is stable, working up to 20 hrs without stopping.

5. The laser machine needs 0.1s to start working after receiving the signal; after printing work, needs 0.1s to transfer the signal to the control system and indicate the work is done.

6. The machine is built with environmentally friendly, green technology.

Key Modules

- Laser Marking module: this system contains a photoelectric sensor, laser marking head, computer operation, control unit, etc. After the photoelectric sensor detects the feeding box, it transmits the signal to the control computer, and then the laser marking head automatically prints the products under the control of the computer. ( laser marking machine is purchased by the buyer)

- Transfer system:

The system contains leveling & shaping, distribution, and feeding modules. After the equipment is started, the leveling & shaping system makes all the cartridge's surface sides ready for marking; then the distribution module classifies the cartridges into groups and the feeding module is used for transporting them to the pointed position for marking.

3. Operation and Control System: PLC - Omron brand + Touch Screen

Working Environment

Working environment temperature: 0 ≤ 45 ℃;

Humidity: 20 ≤ 90% RH;

Power supply: single-phase 220VAC, 50Hz, 1.5KVA

Compressed air: 2 kgf/cm, tolerance: ±10%;

Installation Area: 1800mmX1500mmX1900mm

No strong magnetically zone, and no noxious gas in the workshop

We provide customized lines according to the customer’s products, production throughput, and layout plan of the workshop, please contact us for a free consult. Turnkey service is available.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!