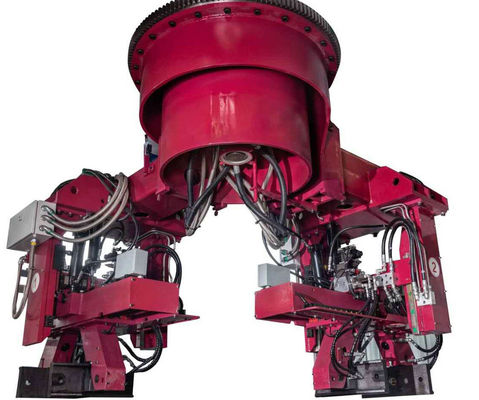

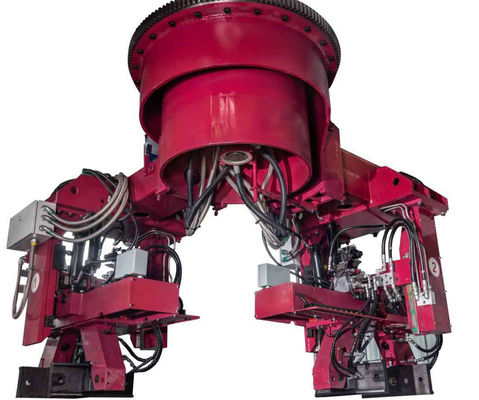

LPDC0201-Low Pressure Die Casting Machine

The LPDC0201 Low pressure die casting equipment consists of the main components: casting device, induction furnace, receiving car, graphite bath, die cleaning device, crane, two manipulators, hydraulic and drives system, pneumatic system, riser tube heating system and control system etc.

Applications:

The Low Pressure Die casting machines are mainly for brass alloy and zinc alloy metal products, especially on faucets, valve bodies and sanitary fittings and accessories

Advantages:

1. High-quality casting and high-precision repeatability, automated casting with servo motor driving, linear guiding rail system;

2. High capacity ranges 400~450 castings per shift (8hrs);

3. Quick die change flange, 5 mins by manually ;

4. Furnace heating method: gas burner is standard and electricity for option;

5. Max. die diemension 550*400mm;

6. The whole set machine is cooled by cooling water for efficient cooling, which highly improves inductor service life;

7. Zinc Oxide dust cleaning unit for furnace cleaning;

8. Industrial PC control with Ethernet cables, die casting programs up to 200 saved, recording & tracking furnace temperature;

9 . Cost-efficient production ( reduced melting loss, multiple die, one-man operation, increased yield);

10. Humanization of the workstation (ergonomic design of the workstation, minimizing heat, noise and danger of accident)

Technical Parameters:

| Code |

Item |

Model: LPDC0201 |

| 1 |

External Size: L*W*H (mm) |

6000*6000*3400 |

| 2 |

Power Rate (KW) |

180 |

| 3 |

Operating Voltage (V) |

380 |

| 4 |

Qty. of Manipulator (sets) |

2 |

| 5 |

Max. Die Mould Weight (KG) |

180 |

| 6 |

Max. Die Mould Dimensions(mm) |

550*400*250 |

| 7 |

Power of Electric Furnace(KW) |

2*80 |

| 8 |

Furnace Melting Capacity (kg/hr) |

520 |

| 9 |

Qty. of Furnace (set) |

1 |

| 10 |

Qty. of Mould Cleaning Bin (set) |

1 |

| 11 |

Qty. of Feeder (sets) |

2 |

| 12 |

Qty. of Grahite Bath (set) |

2 |

| 13 |

Qty. of Crane (set) |

1 |

| 14 |

Max. Loading of Crane (KG) |

500 |

| 15 |

Qty. of Tube (pieces) |

3 |

| 16 |

Gas Pressure (KG) |

6 |

| 17 |

Water Pressure(KG) |

3 |

| 18 |

Max.Temp. of Furnace (℃) |

1250 |

| 19 |

Temp.of Cooling Water(℃) |

20±2 |

| 20 |

Max. Speed of Manipulator |

35° / Sec. |

| 21 |

Max. Clamping Stroke of Mould (mm) |

370 |

| 22 |

Angle Range of Mould Soaking (°) |

0~90 |

| 23 |

Pressure of Thimble (KG) |

540 |

| 24 |

Stroke of Thimble (mm) |

50 |

| 25 |

Pressure of Casting (Bar) |

50~1200 |

Key Components

Please contact us for more specifications with your inquiry today! Our honor to serve you with our best service and highest quality.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!